If you are looking for high-quality products, please feel free to contact us and send an inquiry, email: brad@ihpa.net

Introduction to Waterborne Calcium Stearate

Waterborne calcium stearate has become a vital material in modern-day industrial applications as a result of its eco-friendly profile and multifunctional abilities. Unlike traditional solvent-based ingredients, waterborne calcium stearate supplies a lasting alternative that meets expanding needs for low-VOC (unpredictable organic substance) and safe formulas. As governing stress places on chemical use throughout markets, this water-based diffusion of calcium stearate is obtaining traction in coatings, plastics, construction products, and more.

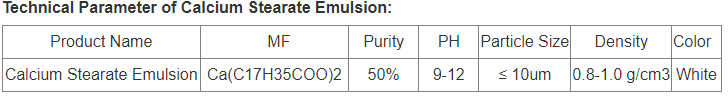

(Parameters of Calcium Stearate Emulsion)

Chemical Structure and Physical Characteristic

Calcium stearate is a calcium salt of stearic acid with the molecular formula Ca(C ₁₈ H ₃₅ O TWO)TWO. In its conventional form, it is a white, waxy powder understood for its lubricating, water-repellent, and stabilizing homes. Waterborne calcium stearate refers to a colloidal diffusion of great calcium stearate fragments in an aqueous medium, often stabilized by surfactants or dispersants to prevent jumble. This solution allows for easy incorporation into water-based systems without endangering performance. Its high melting point (> 200 ° C), low solubility in water, and excellent compatibility with various resins make it excellent for a variety of functional and architectural duties.

Production Process and Technological Advancements

The manufacturing of waterborne calcium stearate usually includes reducing the effects of stearic acid with calcium hydroxide under regulated temperature level and pH conditions to develop calcium stearate soap, complied with by diffusion in water utilizing high-shear blending and stabilizers. Recent advancements have concentrated on improving particle dimension control, boosting solid web content, and lessening ecological impact through greener handling approaches. Innovations such as ultrasonic-assisted emulsification and microfluidization are being checked out to enhance dispersion stability and practical performance, making certain consistent high quality and scalability for industrial customers.

Applications in Coatings and Paints

In the layers sector, waterborne calcium stearate plays an important duty as a matting representative, anti-settling additive, and rheology modifier. It helps reduce surface area gloss while maintaining movie stability, making it particularly helpful in building paints, timber finishes, and industrial finishes. In addition, it improves pigment suspension and protects against drooping during application. Its hydrophobic nature additionally boosts water resistance and resilience, contributing to longer coating life-span and minimized maintenance costs. With the shift towards water-based finishes driven by ecological laws, waterborne calcium stearate is ending up being a necessary formula part.

( TRUNNANO Calcium Stearate Emulsion)

Role in Plastics and Polymer Handling

In polymer manufacturing, waterborne calcium stearate serves mostly as an inner and outside lubricating substance. It facilitates smooth melt flow throughout extrusion and shot molding, reducing die accumulation and enhancing surface area finish. As a stabilizer, it neutralizes acidic residues created throughout PVC handling, preventing deterioration and discoloration. Compared to standard powdered forms, the waterborne variation uses far better dispersion within the polymer matrix, bring about enhanced mechanical properties and process performance. This makes it particularly valuable in stiff PVC accounts, cable televisions, and films where appearance and efficiency are critical.

Usage in Building And Construction and Cementitious Equipment

Waterborne calcium stearate locates application in the building field as a water-repellent admixture for concrete, mortar, and plaster products. When incorporated right into cementitious systems, it develops a hydrophobic barrier within the pore framework, considerably lowering water absorption and capillary increase. This not only boosts freeze-thaw resistance yet also protects against chloride ingress and rust of embedded steel reinforcements. Its simplicity of assimilation into ready-mix concrete and dry-mix mortars positions it as a preferred option for waterproofing in infrastructure jobs, passages, and below ground structures.

Environmental and Health And Wellness Considerations

One of one of the most compelling benefits of waterborne calcium stearate is its environmental profile. Free from unstable natural substances (VOCs) and hazardous air toxins (HAPs), it aligns with international initiatives to decrease industrial emissions and advertise environment-friendly chemistry. Its biodegradable nature and reduced toxicity further support its fostering in eco-friendly product lines. Nonetheless, proper handling and formula are still required to ensure worker safety and avoid dirt generation during storage and transportation. Life cycle assessments (LCAs) increasingly prefer such water-based additives over their solvent-borne counterparts, enhancing their role in sustainable production.

Market Trends and Future Outlook

Driven by stricter environmental regulations and increasing customer understanding, the market for waterborne ingredients like calcium stearate is expanding swiftly. The Asia-Pacific region, in particular, is seeing solid development as a result of urbanization and automation in countries such as China and India. Key players are investing in R&D to develop customized grades with enhanced performance, including heat resistance, faster dispersion, and compatibility with bio-based polymers. The combination of electronic modern technologies, such as real-time monitoring and AI-driven formula tools, is expected to more maximize efficiency and cost-efficiency.

Final thought: A Lasting Foundation for Tomorrow’s Industries

Waterborne calcium stearate stands for a considerable development in practical materials, providing a balanced blend of efficiency and sustainability. From finishes and polymers to building and past, its flexibility is reshaping exactly how markets come close to formulation design and process optimization. As companies aim to meet advancing regulatory requirements and customer assumptions, waterborne calcium stearate stands apart as a trusted, versatile, and future-ready solution. With ongoing innovation and deeper cross-sector partnership, it is positioned to play an also higher role in the shift toward greener and smarter making practices.

Vendor

Cabr-Concrete is a supplier under TRUNNANO of Concrete Admixture with over 12 years of experience in nano-building energy conservation and nanotechnology development. It accepts payment via Credit Card, T/T, West Union and Paypal. TRUNNANO will ship the goods to customers overseas through FedEx, DHL, by air, or by sea. If you are looking for Concrete foaming agent, please feel free to contact us and send an inquiry. (sales@cabr-concrete.com) Tags: calcium stearate,ca stearate,calcium stearate chemical formula

All articles and pictures are from the Internet. If there are any copyright issues, please contact us in time to delete.

Inquiry us