About Zinc Stearate Powder:Zinc Stearate Powder is a fine white powder in appearance, smooth to the touch, no sandy feeling, and has a fatty odor.Tqhp is a trusted global Zinc Stearate Powder. Feel…

About Zinc Stearate Powder:

Zinc Stearate Powder is a fine white powder in appearance, smooth to the touch, no sandy feeling, and has a fatty odor.

Tqhp is a trusted global Zinc Stearate Powder. Feel free to send an inquiry to get the latest price of Zinc Stearate Powder if you would like to buy Zinc Stearate Powder in bulk.

If you want to know zinc stearate price, please send inquiry to sales1@rboschco.com

Product Performance of Zinc Stearate Powder:

Zinc Stearate Powder is insoluble in water, but soluble in other organic solvents such as hot ethanol, turpentine and benzene. Zinc stearate is decomposed into stearic acid and corresponding zinc salts in the presence of strong acid.

Technical Parameter of Zinc Stearate Powder:

| Product Name | Short Name | Melting Point | Zn Content | Particle Size | Appearance |

|---|

| Zinc Stearate Powder | N/A | 120±℃ | 10.3-11.3% | 325 mesh | white powder |

Applications of Zinc Stearate Powder:

Zinc stearate uses in the processing of non-toxic PVC products. Zinc stearate uses in cosmetics. It has a synergistic effect with calcium stearate and barium stearate, which can effectively improve the light stability of PVC products. The dosage in PVC processing is usually<1 portion;

Zinc stearate in rubber compounds, and it is also used in the manufacture of PP, PE, PS, EPS polymerization additives and pencil leads. The general dosage is 1-3 portion.

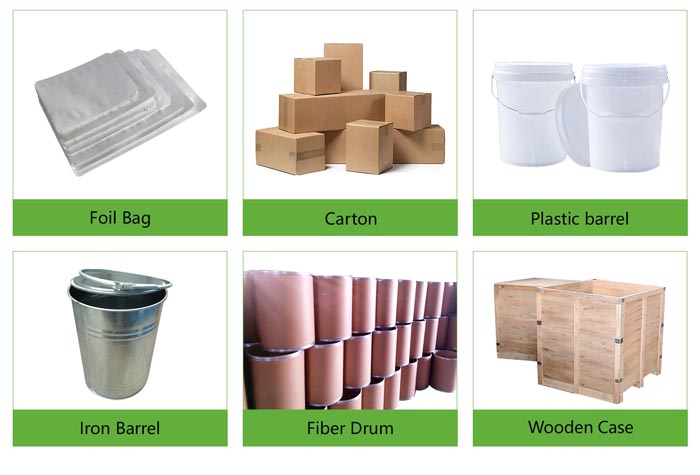

Packing & Shipping of Zinc Stearate Powder:

We have many different kinds of packing which depend on Zinc Stearate Powder quantity.

Zinc Stearate Powder packing: 20kg/bag, then put on pallet.

Zinc Stearate Powder shipping: could be shipped out by sea, by air, by express as soon as possible once payment receipt.

Zinc Stearate Powder Properties |

| Other Names | N/A |

| CAS No. | 557-05-1 |

| Compound Formula | [CH3(CH2)16COO]2Zn |

| Molecular Weight | N/A |

| Appearance | White powder |

| Melting Point | 120±5℃ |

| Boiling Point | N/A |

| Density | N/A |

| Solubility in H2O | No |

| Exact Mass | N/A |

Zinc Stearate Powder Health & Safety Information |

| Signal Word | N/A |

| Hazard Statements | N/A |

| Hazard Codes | N/A |

| Risk Codes | N/A |

| Safety Statements | N/A |

| Transport Information | N/A |

About Calcium Stearate Emulsion:Calcium stearate is an organic compound, molecular formula C36H70CAO4, white powder is insoluble in water, which can be used as waterproof, lubricants, and plastic auxiliary tools. Calcium stearate is calcium…

About Calcium Stearate Emulsion:

Calcium stearate is an organic compound, molecular formula C36H70CAO4, white powder is insoluble in water, which can be used as waterproof, lubricants, and plastic auxiliary tools. Calcium stearate is calcium carboxylate and is divided into calcium soap. It is some lubricants, surfactants, and components of many foods. This is a white waxy force. The calcium stearate emulsion is a stabilizer and lubricant of polychloroacetic acid, but the stable effect is poor, long-term thermally stable effect is good, and non-toxic food packaging, medical device and other soft film vessels. In polyethylene, polypropylene as a halogen absorber, the catalyst in the resin can eliminate the adverse effects of resin color and stability. It can also be widely used as a lubricant of polyolefin fibers and mold plastic, or a phenolic, amino group such as a phenolic, amino group, and a polyester reinforced plastic moisturizing and release agent, a water repeater of grease, and a water repeater of textiles. Paint flat light, etc. Tqhp is a trusted global Calcium Stearate Emulsion supplier. Feel free to send an inquiry about the latest price of Calcium Stearate Emulsion at any time.

Product Performance of Calcium Stearate Emulsion:

Calcium stearate liquid refers to water-based calcium stearate, also known as calcium stearate emulsion, which is widely used in industrial fields. Calcium stearate emulsion has ultra-fine, lubricating and delicate feeling, good thermal denaturation resistance, and good transparency. Good defoaming, excellent dispersibility, anti-settling performance, sandability and yellowing resistance.

Technical Parameter of Calcium Stearate Emulsion:

| Product Name | MF | Purity | PH | Particle Size | Density | Color |

| Calcium Stearate Emulsion | Ca(C17H35COO)2 | 50% | 9-12 | ≤ 10um | 0.8-1.0 g/cm3 | White |

How is Calcium Stearate Emulsion produced?

Preparation of calcium stearate emulsion by saponification synthesis method

Add the CaCl solution and the NaOH solution to the reactor according to the stoichiometric ratio, then add the dispersant, emulsifier A, emulsifying aid and CMC under agitation, and then mix evenly to obtain an emulsion; add stearic acid and catalyst to the emulsion, and keep the temperature constant Stir to obtain a mixed solution; stearic acid and calcium hydroxide react to form calcium stearate, which is uniformly dispersed in the emulsion. Finally, n-octanol and modified polyvinyl alcohol aqueous solution (mass percentage concentration is 10%) are added and stirred to react 0.5- 20s, quickly cooled to room temperature, high-speed shear dispersion for 10-30 minutes to obtain calcium stearate emulsion, and its solid content, viscosity, dispersibility, etc. were analyzed and determined.

Applications of Calcium Stearate Emulsion:

Calcium stearate is mainly used as an acid scavenger, release agent and lubricant in the plastics industry, used for building waterproofing, and used as an anti-caking additive in medicine and cosmetics.

1. Calcium stearate emulsion is the stabilizer and lubricant of polychloroacetic acid, but its stability effect is poor, and its long-term thermal stability effect is still good. Can be used for non-toxic food packaging, medical equipment and other soft film appliances.

2. Calcium stearate emulsion used as halogen adsorbent in polyethylene and polypropylene can eliminate the adverse effect of a residual catalyst in the resin on the color and stability of the resin.

3. Calcium stearate emulsion can also be widely used as a lubricant for polyolefin fibers and molded products.

4. Calcium stearate emulsion can be used as phenolic, amino and other thermosetting plastics, polyester reinforced plastics lubricant and release agent, grease thickening agent.

5. Calcium stearate emulsion can be used as a waterproofing agent for textiles and a smoothing agent for paints.

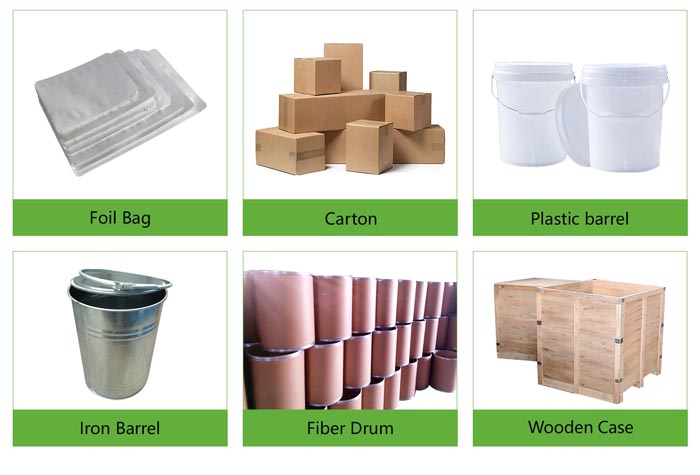

Packing & Shipping of Calcium Stearate Emulsion:

We have many different kinds of packing which depends on calcium stearate emulsion quantity.

Calcium stearate emulsion packing: 1kg/bottle, 25kg/barrel, or 200kg/ barrel.

Calcium stearate emulsion shipping: could be shipped out by sea , by air, by express as soon as possible once payment receipt.

Calcium Stearate Emulsion Properties |

| Other Names | N/A |

| CAS No. | N/a |

| Compound Formula | Ca(C17H35COO)2 |

| Molecular Weight | N/A |

| Appearance | White Emulsion |

| Melting Point | 150-155℃ |

| Boiling Point | N/A |

| Density | 0.8-1.0 g/cm3 |

| Solubility in H2O | N/A |

| Exact Mass | N/A |

Calcium Stearate Emulsion Health & Safety Information |

| Signal Word | N/A |

| Hazard Statements | N/A |

| Hazard Codes | N/A |

| Risk Codes | N/A |

| Safety Statements | N/A |

| Transport Information | N/A |

About Water-Based Boron Nitride Emulsion:Water-Based Boron Nitride Emulsion-Hexagonal Boron Nitride Coating. The water-based coating has excellent lubrication and release properties. It is formed by matching high-purity BN powder base material and high-temperature…

About Water-Based Boron Nitride Emulsion:

Water-Based Boron Nitride Emulsion-Hexagonal Boron Nitride Coating. The water-based coating has excellent lubrication and release properties. It is formed by matching high-purity BN powder base material and high-temperature bonding. High chemical purity boron nitride particles and inorganic binder form a very superior formula, which can provide a fluid and continuous coating on the surface with excellent adhesion. Also known as boron nitride coating and boron nitride lubricant.

Boron nitride coating is an inert inorganic high-temperature lubricating material, which does not bond or infiltrate the molten metal. It can completely protect the surface of refractory materials or ceramic vessels that directly contact with molten aluminum, magnesium, zinc alloy and molten slag, and greatly extend this kind of utensils. Life.

The hexagonal boron nitride suspension has high thermal conductivity. It does not impregnate molten metal and can be directly applied to the surface that needs to be protected, even if the surface is already hot. It remains stable at high temperatures and does not react to metal, glass or molten salt. Boron nitride coatings are provided in a liquid form suitable for brushing, which can be diluted with water to the concentration for spraying and dipping, and are suitable for various porous and non-porous materials, including graphite, metals, ceramics and organics. Feel free to send an inquiry to get the latest price if you would like to buy Water-Based Boron Nitride Emulsion in bulk.

Properties of Water-Based Boron Nitride Emulsion:

Water-based boron nitride Emulsion has no pollution to the environment and no harm to the human body. Non-toxic, no odor. Boron nitride coating has good heat resistance, up to 400-1700℃, it has anti-corrosion performance and long service life. It has good water resistance, resistance to salt spray and organic solvents.

How is Water-Based Boron Nitride Emulsion produced?

Brushing method: It is recommended to gently stir the paint before use. When it needs to be diluted, dilute it with distilled water.

Spraying method: use a spray gun or a similar spray gun with a pressure of 50-60 psi (0.35-0.42MPa). Stir the paint before spraying. When it needs to be diluted, dilute it with distilled water.

Dip coating method: When dilution is needed, dilute with distilled water. Between two dips, it needs to be dried at 80°C for 40 minutes.

Application of Water-Based Boron Nitride Emulsion:

Aqueous boron nitride emulsions have been widely used in aerospace, petroleum and petrochemical, metallurgy, power and military systems. They are suitable for chimney flue, high-temperature steam pipe, heat exchanger, high-temperature furnace, high-temperature desulfurization equipment, petroleum and petrochemical cracking equipment, engine parts and exhaust pipe anti-corrosion.

Boron nitride emulsion can be used in aluminum, magnesium, zinc and other alloy casting, gravity/low-pressure casting, forging, powder metallurgy and other fields.

Boron nitride emulsion is widely applied to the surface of launder, distribution launder, casting table lining, filter box, adapter plate, cast-rolling nozzle material, skimmer, ladle and other materials to protect the mold from corrosion and extend the use of refractory materials. life;

In the production process, the boron nitride emulsion prevents fine impurities from penetrating into the molten metal, causing secondary pollution and greatly improving product quality.

Boron nitride emulsion has excellent lubricity and anti-oxidation ability in high-temperature environments, even at extremely high temperatures, it still maintains its unique lubricity, non-stick, anti-sticking and anti-corrosion and oxidation of metal or graphite.

In addition to the protection of various refractory materials, boron nitride emulsions also have excellent anti-chemical corrosion and anti-adhesion protection effects in other fields.

Most molten metals, salts, fluxes and slag cannot make the boron nitride emulsion wet.

Boron nitride emulsion is resistant to molten metal corrosion and light metal scum.

Excellent separation plane/unusual color of boron nitride emulsion.

Boron nitride emulsion helps to remove solidified metal.

Technical Data of Water-Based Boron Nitride Emulsion:

| Product Name | Boron Nitride Emulsion |

| Chemical Formula | BN |

| Appearance | White Emulsion |

| Solid Content | 10-12% |

| PH | 7-8 |

| Particle Size D50 | ≤10um |

| Density | 0.8-1.0 g/cm3 (25℃) |

| Viscossity | ≤500 mpa.s (25℃) |

Packing & Shipping of Water-Based Boron Nitride Emulsion:

We have many different kinds of packing which depend on the Water-based boron nitride Emulsion quantity.

Water-based boron nitride Emulsion packing: 25kg/barrel, or as your request.

Water-based boron nitride Emulsion shipping: could be shipped out by sea, by air, by express as soon as possible once payment receipt.

Boron Nitride Emulsion Properties |

| Other Names | Boron Nitride Emulsion, water-based nitride emulsion, water-based boron nitride |

| CAS No. | N/A |

| Compound Formula | BN |

| Molecular Weight | N/A |

| Appearance | White Emulsion |

| Melting Point | N/A |

| Solubility in water | N/A |

| Density | 0.8-1.0 g/cm3 (25℃) |

| Purity | N/A |

| Particle Size | N/A |

| Boling point | N/A |

| Specific Heat | N/A |

| Thermal Conductivity | N/A |

| Thermal Expansion | N/A |

| Young’s Modulus | N/A |

| Exact Mass | N/A |

| Monoisotopic Mass | N/A |

| | |

| | |

Boron Nitride Emulsion Health & Safety Information |

| Safety Warning | N/A |

| Hazard Statements | N/A |

| Flashing point | N/A |

| Hazard Codes | N/A |

| Risk Codes | N/A |

| Safety Statements | N/A |

| RTECS Number | N/A |

| Transport Information | N/A |

| WGK Germany | N/A |